Page 403 - JBS_Core_Catalogue_2024_V1

P. 403

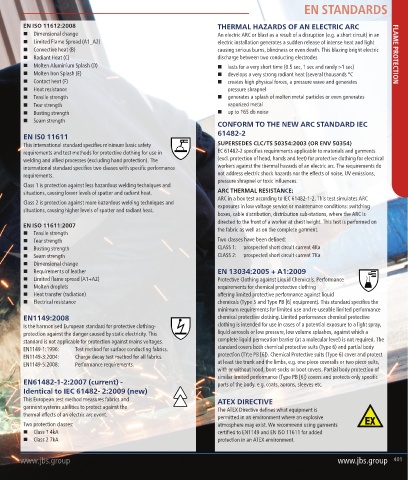

EN STANDARDS

EN ISO 11612:2008 THERMAL HAZARDS OF AN ELECTRIC ARC

Dimensional change An electric ARC or blast as a result of a disruption (e.g. a short circuit) in an

Limited Flame Spread (A1_A2) electric installation generates a sudden release of intense heat and light

Convective heat (B) causing serious burns, blindness or even death. This blazing bright electric

Radiant Heat (C) discharge between two conducting electrodes FLAME PROTECTION

Molten Aluminium Splash (D) lasts for a very short time (0.5 sec, 1 sec and rarely >1 sec)

Molten Iron Splash (E) develops a very strong radiant heat (several thousands °C

Contact heat (F) creates high physical forces, a pressure wave and generates

Heat resistance pressure shrapnel

Tensile strength generates a splash of molten metal particles or even generates

Tear strength vaporized metal

Busting strength up to 165 db noise

Seam strength CONFORM TO THE NEW ARC STANDARD IEC

61482-2

EN IS0 11611

This international standard specifies minimum basic safety SUPERSEDES CLC/TS 50354:2003 (OR ENV 50354)

requirements and test methods for protective clothing for use in EC 61482-2 specifies requirements applicable to materials and garments

welding and allied processes (excluding hand protection). The (excl. protection of head, hands and feet) for protective clothing for electrical

international standard specifies two classes with specific performance workers against the thermal hazards of an electric arc. The requirements do

requirements. not address electric shock hazards nor the effects of noise, UV emissions,

pressure shrapnel or toxic influences.

Class 1 is protection against less hazardous welding techniques and

situations, causing lower levels of spatter and radiant heat. ARC THERMAL RESISTANCE:

ARC in a box test according to IEC 61482-1-2. This test simulates ARC

Class 2 is protection against more hazardous welding techniques and exposures in low voltage service or maintenance conditions: switching

situations, causing higher levels of spatter and radiant heat.

boxes, cable distribution, distribution sub-stations, where the ARC is

directed to the front of a worker at chest height. This test is performed on

EN ISO 11611:2007 the fabric as well as on the complete garment.

Tensile strength

Tear strength Two classes have been defined:

Busting strength CLASS 1: prospected short circuit current 4Ka

Seam strength CLASS 2: prospected short circuit current 7Ka

Dimensional change

Requirements of leather EN 13034:2005 + A1:2009

Limited flame spread (A1+A2) Protective Clothing against Liquid Chemicals. Performance

Molten droplets requirements for chemical protective clothing

Heat transfer (radiation) offering limited protective performance against liquid

Electrical resistance chemicals (Type 5 and Type PB [6] equipment). This standard specifies the

minimum requirements for limited use and re-useable limited performance

EN1149:2008 chemical protective clothing. Limited performance chemical protective

Is the harmonised European standard for protective clothing- clothing is intended for use in cases of a potential exposure to a light spray,

protection against the danger caused by static electricity. This liquid aerosols or low pressure, low volume splashes, against which a

standard is not applicable for protection against mains voltages. complete liquid permeation barrier (at a molecular level) is not required. The

EN1149-1:1996: Test method for surface conducting fabrics. standard covers both chemical protective suits (Type 6) and partial body

protection (TY;e PB [6]). Chemical Protective suits (Type 6) cover and protect

EN1149-3:2004: Charge decay test method for all fabrics.

EN1149-5:2008: Performance requirements. at least the trunk and the limbs, e.g. one piece coveralls or two piece suits,

with or without hood, boot-socks or boot covers. Partial body protection of

similar limited performance (Type PB [6]) covers and protects only specific

EN61482-1-2:2007 (current) - parts of the body. e.g. coats, aprons, sleeves etc.

Identical to IEC 61482- 2:2009 (new)

This European test method measures fabrics and ATEX DIRECTIVE

garment systems abilities to protect against the

The ATEX Directive defines what equipment is

thermal effects of an electric arc event.

permitted in an environment where an explosive

Two protection classes: atmosphere may exist. We recommend using garments

Class 1 4kA certified to EN1149 and EN ISO 11611 for added

Class 2 7kA protection in an ATEX environment.

www.jbs.group www.jbs.group 401