Page 14 - JBS_Core_Catalogue_2024_V1

P. 14

EN STANDARDS

Safety Footwear

SAFETY FOOTWEAR SAFETY FOOTWEAR Legislation S1 - additionally featuring antis-static properties and P - protection from upward penetration provided by a

EN ISO 20345:2011 is the current standard to which new and

composite or steel midsole (not used in conjunction

recently certified footwear has to conform (whilst stock

fully enclosed and energy absorbing heel unit.

with S3 or S5)

rotates some safety footwear may have been tested to the

previous standard). The standard to which the footwear

leather

conforms will be identified on the product information label

C - conductive properties helping to prevent the build-

S3 - additionally featuring cleated outsole and pierce

within the footwear. S2 - additionally featuring the use of water resistant M - metatarsal impact protection

resistant midsole up of static (but no protection against electric shock)

The standard requires the inclusion of a 200 joule toecap for

impact protection. In addition to the over arching S4 - rubber or polymeric waterproof footwear with 200 A - anti-static properties to prevent the build-up of

requirements of the standards there are a number of joule toecap, anti-static properties and energy static and give limited protection against electric shock

progressive ratings which assist selection of footwear absorbing heel unit. from nominal mains voltage

appropriate for varying workplace hazards. S5 - additionally featuring cleated outsole and pierce HI - insulation against heat

These are: resistant midsole CI - insulation against cold

SB - safety basic footwear meeting all the minimum Additional protective features can be built into the footwear E - energy absorption in heel unit

requirements of the standard and are identified by the following suffixes:

WRU - water resistant uppers

Buying Guide Sizing

Safety footwear often carries European sizing, please

see below for a comparison table.

Choose the right footwear

Most workplaces have varying requirements for the provision of safety footwear, which is why we offer

a comprehensive range within which you should be able to identify appropriate footwear to meet the Shoe Size Conversion Table

needs of your workforce whatever the hazards identified in your risk assessment.

This table is for guidance only as sizes are not standardised.

Whilst protection is paramount it is recognised that with long wear periods, often in hostile conditions, British 2 3 4 5 6 7 8 9 10 11 12 13

wearer acceptance, design, brand and comfort are additional considerations. We therefore offer varying EU 35 36 37 38 39 41 42 43 44 46 47 48

styles from executive shoes to heavy duty rigger boots.

Slip Resistance Maintenance

As with all footwear it is essential that, to achieve

Slips, trips and falls are an ever present hazard within most workplaces and safety footwear can play

it’s part in preventing injury, particularly from slips, by featuring slip resistant soles. optimum performance of the properties built in to the

safety footwear at time of manufacture, safety

For many years the test of choice for slip resistance has been SATRA’s TM144 standard which evaluates footwear is cleaned and maintained regularly.

the performance of the sole unit on a water wet quarry tile. Well established styles of footwear are

likely to have been tested to TM144 and will be identified as such by the TM144 icon.

However with regard to new styles of footwear undergoing periodic re-testing the recently established Safety Icons Key

EN ISO 13287 with it’s progressive SRA, SRB and SRC ratings has become more widely used.

Details of the EN ISO 13287 testing requirements are shown in the table below. S3

EN ISO 20345 Anti-Slip Anti-Static Composite Composite

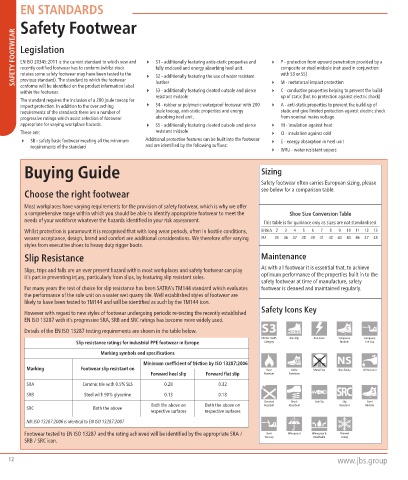

Slip resistance ratings for industrial PPE footwear in Europe Category Midsole Toe-Cap

Marking symbols and specifications

Minimum coefficient of friction by ISO 13287:2006

Marking Footwear slip resistant on Heat Ankle Metal Free Non-Safety Oil Resistant

Forward heel slip Forward flat slip Resistant Protection

SRA Ceramic tile with 0.5% SLS 0.28 0.32

SRC

SRB Steel with 90% glycerine 0.13 0.18

Chemical Shock Side Zip Slip Steel

Both the above on Both the above on Resistant Absorbent Resistant Midsole

SRC Both the above

respective surfaces respective surfaces

NB: ISO 13287:2006 is identical to EN ISO 13287:2007

Footwear tested to EN ISO 13287 and the rating achieved will be identified by the appropriate SRA / Steel Waterproof Waterproof & Thermal

Toe-Cap Breathable Lining

SRB / SRC icon.

12 www.jbs.group